Auto Parts Industry to Government Secure Raw Materials or Risk EV Progress

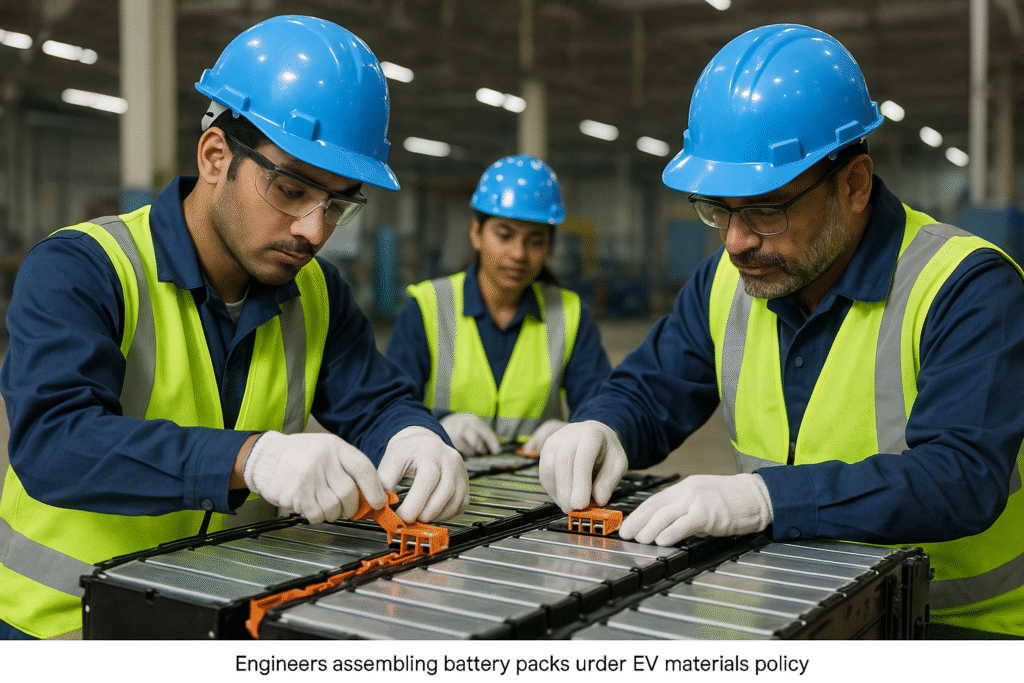

As India pushes for faster EV adoption, industry leaders say the country urgently needs a comprehensive EV materials policy to avoid future supply risks.

Across the Indian auto manufacturing landscape, parts suppliers and engineering firms are raising a common red flag — we don’t have a steady source for the materials needed to power EVs.

A Workshop-Level Warning: India Needs a National Plan for EV Materials

Small and medium component manufacturers are struggling to meet the growing demand for EV parts, and the main bottleneck isn’t machines or manpower — it’s raw materials like lithium, cobalt, graphite, and rare earth elements.

“Every week we get more orders for EV parts, but securing materials is turning into a guessing game,” said Rajendra Shekhawat, who runs a parts factory outside Pune. “We rely on imports, and prices swing without warning.”

His worry echoes throughout the sector — India wants to lead in EVs, but is missing a national plan to secure the core ingredients. As demand grows for electric vehicles, India lacks a formal EV materials policy to ensure stable access to key minerals.

No Backup Plan Without an EV Materials Policy

India doesn’t produce much of what it needs for batteries and EV motors. That means companies are at the mercy of global markets and foreign suppliers. A disruption in another country — whether political or environmental — could put production on pause here at home.

That’s why auto parts makers are calling for a dedicated raw material strategy. They aren’t asking for handouts — just clear direction and support.

What the Industry Wants from a National Plan for EV Materials

Here’s what auto suppliers want the government to consider:

- Mapping India’s own mineral reserves and making exploration a priority

- Signing long-term contracts with countries rich in EV minerals

- Recycling old batteries to reclaim valuable metals

- Creating a central stockpile of high-demand materials for emergencies

- Incentives for private investment in processing and refining facilities

These steps, they believe, can insulate Indian manufacturers from international volatility — and keep the EV journey on track.

More Than Just Cars: The Need for an EV Materials Policy

This isn’t only about automakers. Without a strong EV materials policy, India’s entire green energy plan could face serious delays. Solar panels, battery storage units, and even wind turbines rely on many of the same critical materials used in electric vehicles.

“If we treat raw materials like an afterthought, the whole ecosystem suffers,” said Swati Kulkarni, a researcher in sustainable technology. “Planning starts underground — literally.”

A Race That Requires Resources

India’s EV goals are ambitious. By 2030, the government wants a majority of new vehicle sales to be electric. But numbers mean little if manufacturers can’t get what they need to build.

Auto part makers aren’t asking for miracles — just the tools to compete. And right now, that tool is a clear national policy on materials that matter.

You May Like Also

India Clears Elon Musk’s Starlink to Offer Satellite Internet: Here’s What Changes Now

Two IAF Pilots Dead in Jet Crash Near Churu, Rajasthan